- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

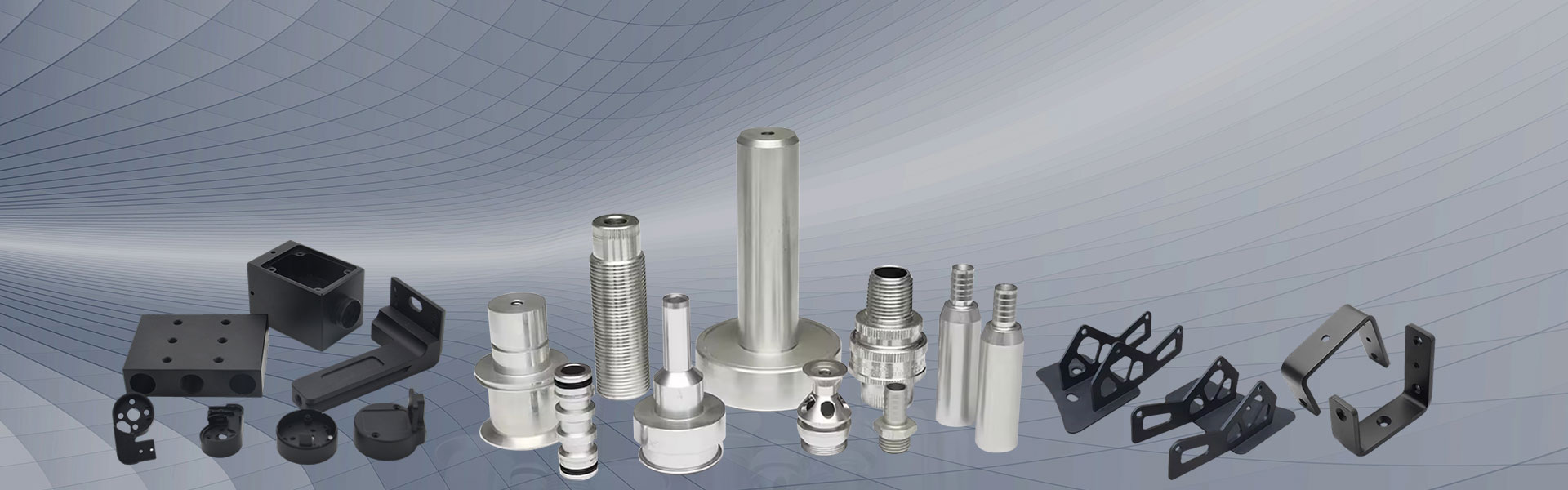

Large Laser Cutting Processing Parts

Send Inquiry

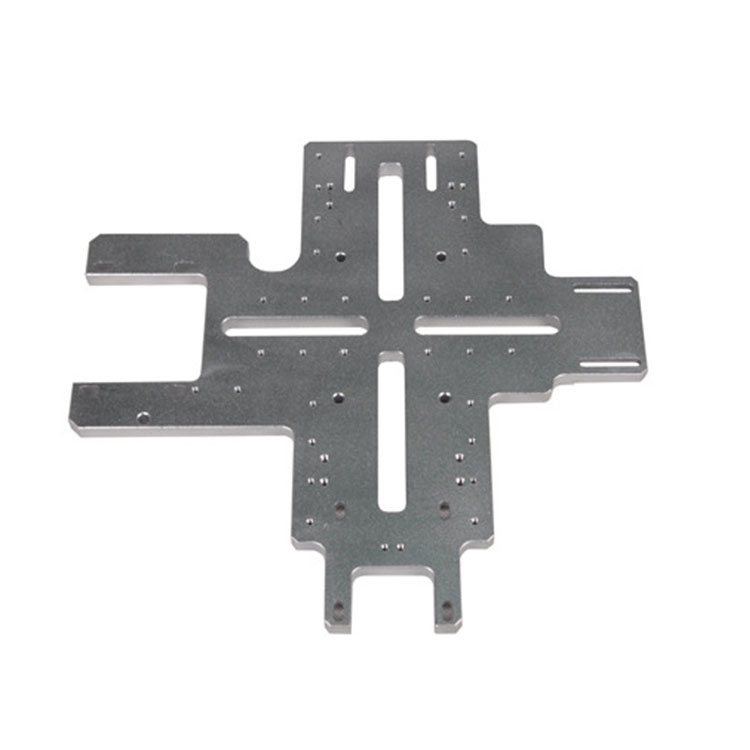

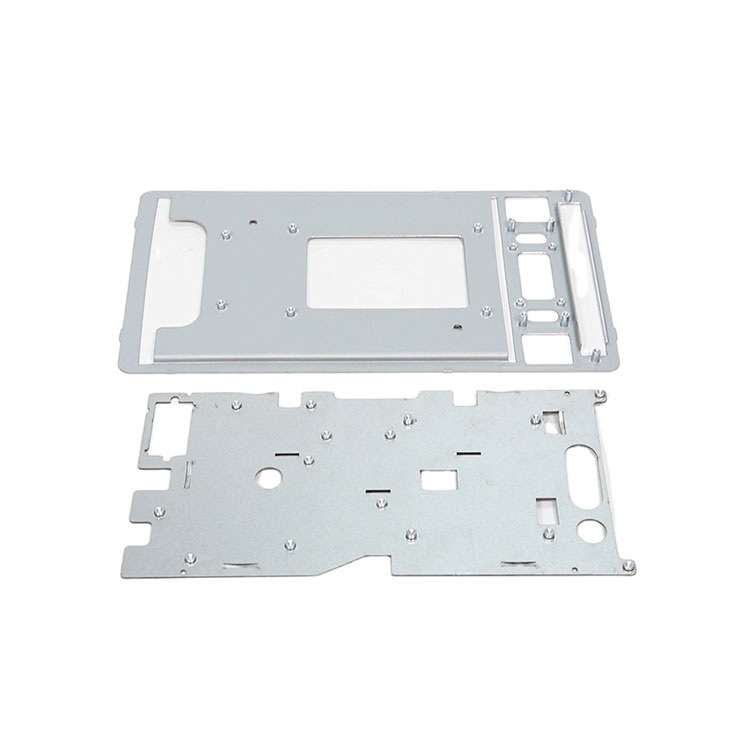

You can confidently source large laser cutting processing parts from KwongTo, our factory specializes in custom metal stamping. Our expertise extends to manufacturing stainless steel stamped sheet metal parts and aluminum stamping parts. Laser cutting technology ensures exceptional precision, allowing for the creation of intricate designs with tight tolerances. The focused laser beam provides precise control over the cutting process, resulting in clean edges and minimal material waste. Our laser cutting machines are versatile, capable of handling various applications such as cutting, engraving, marking, and etching. Whether for prototyping or production, we can accommodate a wide range of part sizes and quantities efficiently. With fast and efficient processing, including the ability to cut through thick materials in a single pass, we ensure rapid production turnaround times with minimal setup requirements.

| Materials | Aluminum, copper, brass, stainless steel, carbon steel, steel, iron, alloy, zinc,titanium, etc. |

| Surface Treatment | Anodizing, Brushing, Galvanized, Laser engraving, Silk printing, Polishing, Powder coating, etc. |

| Tolerance | ±0.1~0.005mm, 100% QC quality inspection before delivery, can provide quality inspection form |

| Testing equipment | RoHS tester , callipers , salt spary tester , 3D coordonate measuring instrument |

| Processing | Pressing, Stamping, Laser cutting, Bending |

| File Formats | Solid Works, Pro/Engineer, AutoCAD(DXF,DWG), PDF, TIF etc. |

| Service Project | Mold design, mold product, and customization of logo, etc. |

| Quality Assurance | ISO9001:2015 Certified.TUV |

| Our Advantages |

1.10+ years of experience in the metal products processing area and advanced processing machines in saving materials; 2.100% QC quality inspection before delivery; 3.Delivery on time: two shifts in production. |