- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

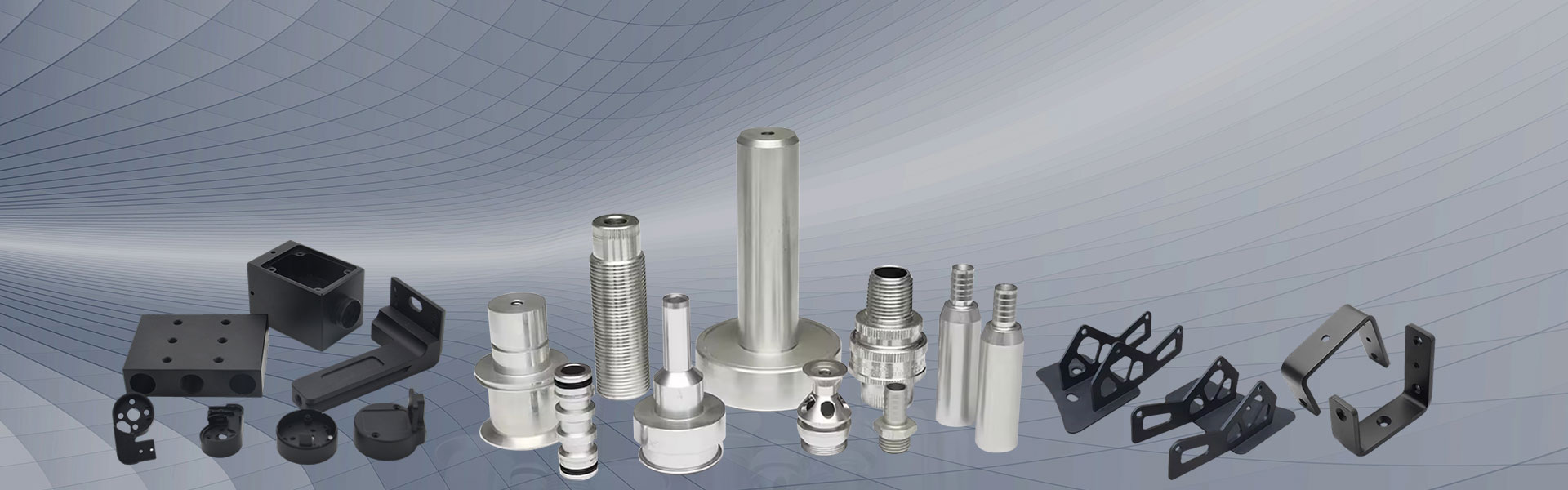

Powder Metallurgy Processing Services

There is almost no limit to the types of metals that can be used in the powder metallurgy process. Despite the wide variety of metals available, certain metals are repeatedly used due to their properties and characteristics. Producers consider certain factors when selecting metals.

The key factors in the selection process are corrosion resistance, hardness, tensile strength, impact toughness, and fatigue strength. Every metal meets some or all of these qualities. The requirements of the part to be produced determine the type of metal selected.

- View as

Powder Metallurgy Production Line Supporting Services

As the professional manufacturer, we would like to provide you Powder Metallurgy Production Line Supporting Services. The rapid growth of powder metallurgy is due to many technological advancements that have streamlined the process and made it so efficient. Many innovations have transformed it from a strange production method to a low-cost method of producing precise and complex parts. Powder metallurgy has become an essential part of automobile and aircraft manufacturing.

Read MoreSend InquiryPowder Metallurgy Mold Design Services

As the professional manufacturer, we would like to provide you Powder Metallurgy Mold Design Services. Powder metallurgy is a manufacturing process that produces precision and high-precision parts by pressing powdered metals and alloys into rigid dies under extreme pressure. With the development and implementation of technological advancements, powder metallurgy has become an important process for producing bushings, bearings, gears, and various structural parts.

Read MoreSend Inquiry