- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

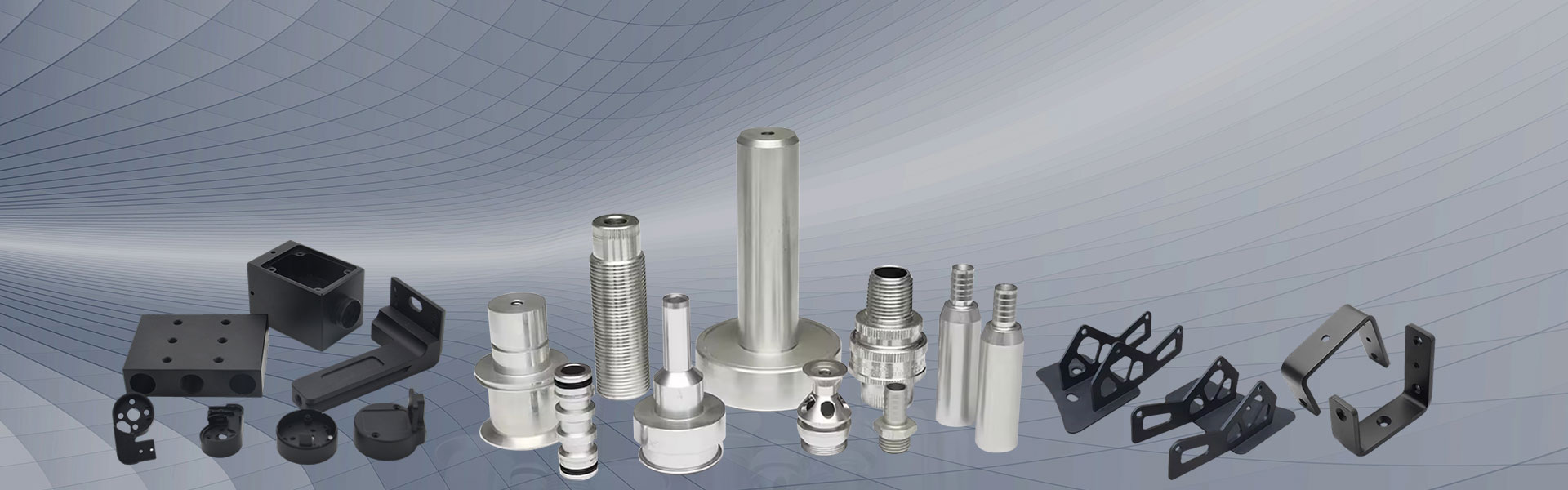

Powder Metallurgy Production Line Supporting Services

Send Inquiry

As the professional manufacturer, we would like to provide you Powder Metallurgy Production Line Supporting Services. Benefits of Using Powder Metallurgy Process

Environmental

The powder metallurgy process is an environmentally friendly production method. An astounding 97% of the material used to produce a part through powder metallurgy becomes part of the final product. Powder metallurgy produces very little to no waste. Every piece of powder that goes into the process is included in the finished component. In addition to being environmentally friendly, not producing waste can also result in significant cost savings.

Flexibility

Unlike other processes, powder metallurgy can mix and blend different metals and non-metals into a product. Unusual and unique combinations can make up a part using a bonding material. Since powder metallurgy can easily combine different materials together and press them into a single shape, complex metallurgical procedures can be avoided.

Powder metallurgy is able to produce any shape, from complex designs to simple gears. The continued development of its technology opens the door to new and diverse applications.

Parts and products produced using powder metallurgy do not require any secondary processing. Each part is close to net shape, which means they do not require any finishing. In addition, powder metallurgy parts have extremely high dimensional accuracy.

Raw Materials

The supply of raw materials has always been a problem for production operations, as a lack of resources can slow down or stop production. Powder metallurgy raw materials are easily available and inexpensive. Powder metals are very common and common materials that can be easily obtained from multiple producers. As powder metallurgy technology has developed, more and more suppliers have developed manufacturing processes to meet the demand.

Repeatability

In mass production, each part, from the first to the last, must meet the dimensional requirements of its design. In some processes, degradation occurs during production, resulting in defects and differences in individual parts. The uniformity and repeatability of the powder metallurgy process avoids such errors and ensures that each part has precise dimensions.

Wear Resistance

It is important that parts installed in cars, aircraft, and machinery have a long service life to avoid expensive repairs and replacements. Parts produced using powder metallurgy have excellent wear resistance and friction coefficient. These factors guarantee that powder metallurgy parts will last long after installation.

Magnetism

A unique feature of powder metallurgy is its ability to combine different metals to manufacture and produce magnetic components and control magnetic properties. The compaction of powdered materials is the same process used to produce magnets, which makes it easy to add to powder metallurgy parts.

Chemical Homogeneity

When a substance is homogeneous, its composition is the same no matter where you extract a sample from the substance. This quality indicates that the properties of the part are consistent throughout its structure. Chemical homogeneity is essential for the uniformity, strength, and durability of a component. All powder metallurgy products have this property; it is the reason they are so long-lasting.

Conclusion

Powder metallurgy is a manufacturing process that produces precision and high-precision parts by pressing powdered metals and alloys into rigid dies under extreme pressure.

The key to the precision and success of powder metallurgy is the sintering process of heating the part to bond the powder particles.

The powder metallurgy process is an ancient and unique method for forming shapes and designs out of ferrous and nonferrous metals.

After returning in the middle of the first industrial revolution, the use of powder metallurgy has steadily grown to become an important part of the production of a variety of parts and products.

There is virtually no limit to the types of metals that can be used in the powder metallurgy process.