- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

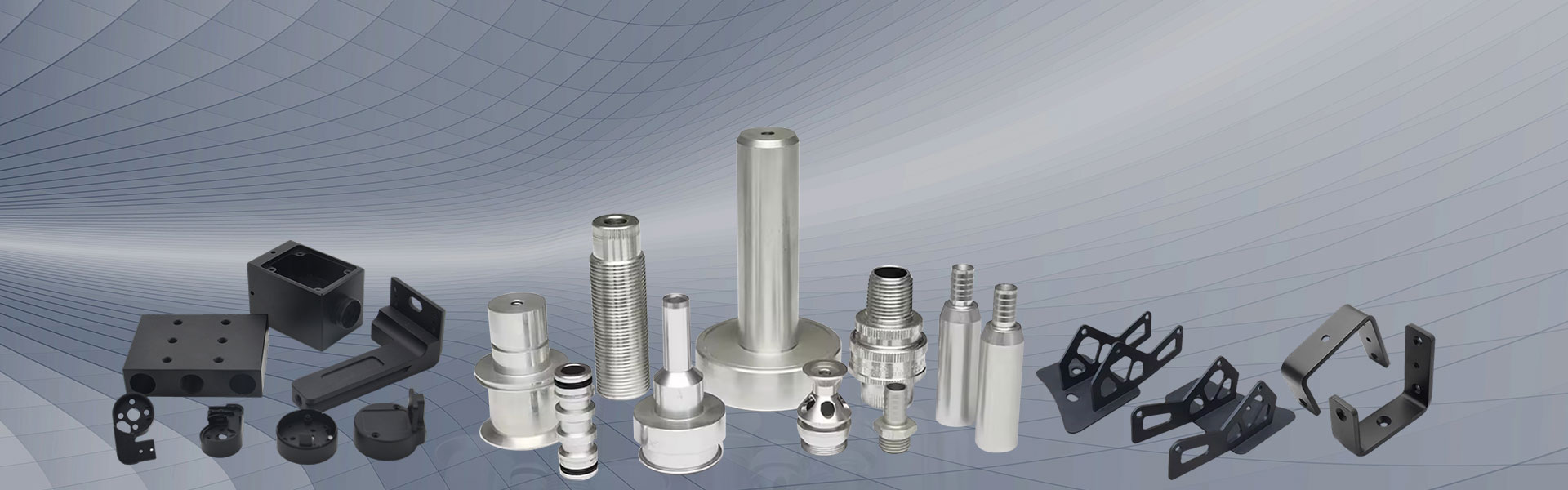

Precision CNC Machining Services

Send Inquiry

You can rest assured to buy KwongTo Precision CNC Machining Services from our factory. Precision CNC machining services provide a cost-effective and reliable solution for producing high-quality components with exceptional accuracy and precision. By leveraging advanced CNC machining technology and expertise, these services help bring innovative designs to life while meeting the demands of modern manufacturing. Key features of precision CNC machining services include:

High Accuracy: Precision CNC machining delivers parts with exceptional accuracy, meeting tight tolerances and dimensional specifications. CNC machines are capable of performing intricate operations with micron-level precision, ensuring consistent quality and repeatability.

Advanced Machining Capabilities: Precision CNC machining services utilize state-of-the-art CNC machines equipped with advanced features such as multi-axis motion control, high-speed spindle capabilities, and automated tool changers. These capabilities enable the production of complex geometries and intricate features with optimal efficiency and precision.

Versatility: Precision CNC machining services work with a wide range of materials, including metals (e.g., aluminum, stainless steel, titanium), plastics (e.g., ABS, PEEK, nylon), and composites. This versatility allows customers to choose the most suitable material for their specific application requirements.

CNC machining service industry specific attributes

Whether to use CNC machining: CNC machining

Material Capabilities: Aluminum, Brass, Bronze, Copper, Tempered Metals, Precious Metals, Stainless Steel, Steel Alloys

Place of Origin: Guangdong, China

Types: Broaching, Drilling, Etching/Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Whether to be micro-machined: Micro-machined

Model: customized

Brand: Customized

Material: According to customer needs

Surface treatment: according to customer requirements

Drawing format: 2D/(PDF/CAD)3D(IGES/STEP)

Tolerance: 0.1 mm

OEM/ODM: OEM ODM CNC milling and turning processing services

Packaging: plastic bag + inner box + carton or wooden box

Sample: within 7 days

3D printing technology: 3D printing technology

Specifications

| Material | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

| Stainless steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. | |

| Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, bronze, red copper | |

| Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK, etc. | |

| Steel type: 1214L/1215/1045/4140/SCM440/40CrMo, etc. | |

| Surface treatment | Anodizing, sandblasting, silk screen, PVD plating, zinc/nickel/chromium/titanium plating, brushing, spray painting, powder coating, passivation, electrophoresis, electrolytic polishing, knurling, laser/etching/engraving, etc. |

| Tolerant | +/-0.01mm, 100% QC quality inspection before shipment, quality inspection form can be provided |

| Drawing accepted | 3D Stp, Step, Igs, Xt, AutoCAD (DXF, DWG), PDF or sample |

| Testing Equipment | Three-dimensional coordinate measuring machine; tool microscope; multi-joint arm; automatic height gauge; manual height gauge; dial indicator; marble platform; roughness measurement |

| Our advantage | More than 10 years of CNC machining experience, with a senior design team to provide perfect modification suggestions |