- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

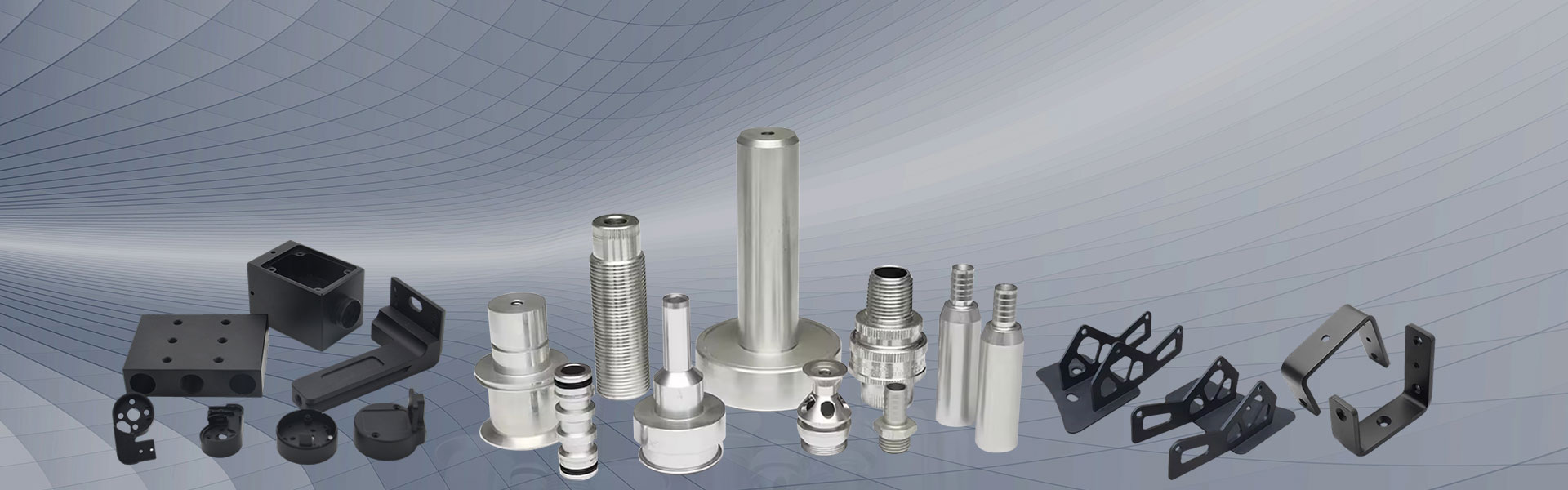

Stamping Production Line Supporting Services

Send Inquiry

As the professional manufacturer, we would like to provide you Stamping Production Line Supporting Services. 1. Process Optimization:

Experienced engineers analyze the entire stamping process to identify potential bottlenecks, inefficiencies, and opportunities for improvement.

Optimization strategies may include streamlining workflows, reducing cycle times, and minimizing material waste.

2. Tooling Maintenance and Repair:

Maintenance programs are developed to ensure the proper care and upkeep of stamping dies, punches, and other tooling components.

Routine inspections and repairs help prevent downtime and extend the lifespan of critical equipment.

3. Quality Control and Assurance:

Quality management systems are implemented to monitor and maintain the integrity of stamped parts throughout the production process.

Inspection protocols, including dimensional checks, surface inspections, and material testing, help identify defects and ensure compliance with specifications.

4. Training and Education:

Training programs are offered to operators, technicians, and other personnel involved in stamping production.

Hands-on training and theoretical instruction cover topics such as equipment operation, safety procedures, troubleshooting, and quality standards.

5. Material Handling and Logistics:

Services may include assistance with material handling, storage, and logistics planning to optimize inventory management and minimize production delays.

Efficient material flow and supply chain management contribute to overall production efficiency and cost-effectiveness.

6. Automation and Integration:

Engineers evaluate opportunities for automation and integration of robotics, sensors, and other advanced technologies into the stamping production line.

Automation solutions help increase throughput, reduce labor costs, and improve consistency and repeatability.

7. Environmental and Safety Compliance:

Services may include assistance with regulatory compliance related to environmental protection, workplace safety, and occupational health.

Safety audits, hazard assessments, and training programs ensure that stamping operations adhere to industry standards and regulations.

8. Continuous Improvement Initiatives:

Continuous improvement methodologies, such as Lean manufacturing and Six Sigma, are applied to drive ongoing efficiency gains and process optimization.

Data analytics and performance metrics are utilized to identify areas for improvement and track progress over time.

9. Technical Support and Troubleshooting:

Dedicated technical support teams provide assistance with equipment troubleshooting, process optimization, and production challenges.

Rapid response times and expert guidance help minimize downtime and maintain production uptime.

By leveraging stamping production line supporting services, manufacturers can enhance the performance, reliability, and competitiveness of their metal stamping operations. These services contribute to improved efficiency, quality, and profitability throughout the production process.