- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

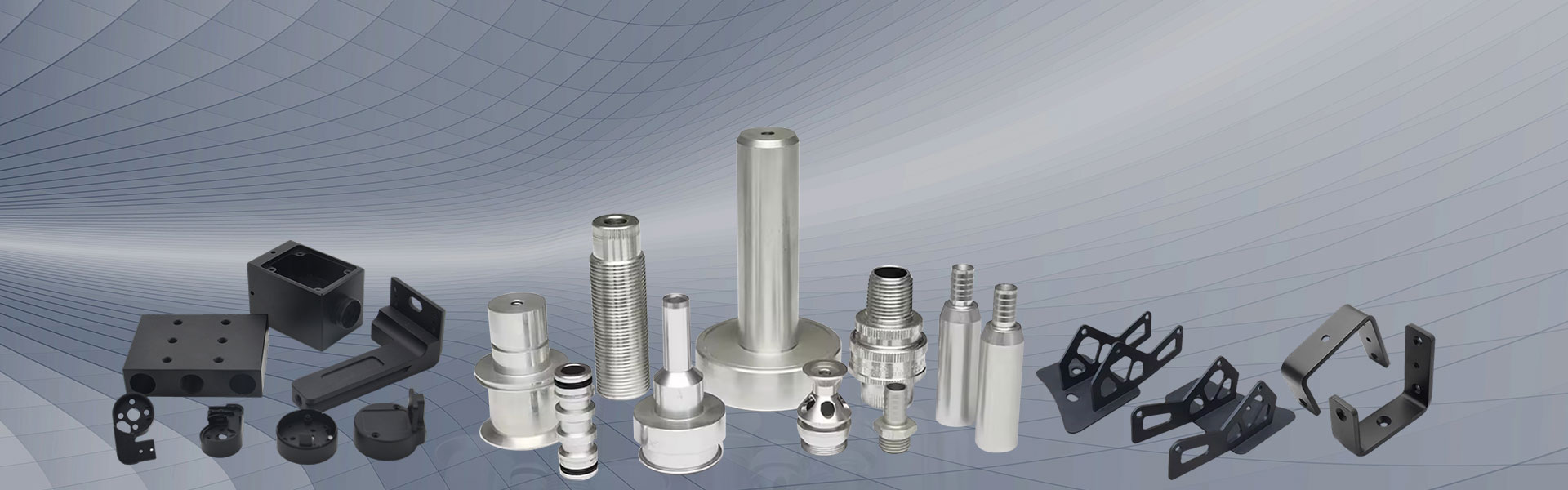

Zinc Alloy Die-Casting Mold Design Services

As the professional manufacturer, we would like to provide you Zinc Alloy Die-Casting Mold Design Services. Zinc alloy die-casting mold design services involve the creation of precise and efficient molds used in the die-casting process to produce zinc alloy parts and components. The design of the mold is crucial to achieving high-quality parts with accurate dimensions and smooth surface finishes.

Send Inquiry

As the professional manufacturer, we would like to provide you Zinc Alloy Die-Casting Mold Design Services. Zinc alloy die-casting mold design services require expertise in mold design principles, materials science, manufacturing processes, and CAD software. By leveraging advanced design tools and simulation techniques, mold designers can optimize the mold design for efficiency, reliability, and cost-effectiveness, ultimately ensuring the production of high-quality zinc alloy parts for various applications.

Common materials

| Stainless Steel Castings: | 304(CF8) , 316(CF8M) , 420 , 431 , 17-4PH , 2205 |

| Alloy Steel Castings: | 42CrMo 、4140、8260 |

| Carbon Steel Castings: | 1020、1045 、C45 、S235JR |

| Bronze and Brass Castings: | H62 , CuZn38 , AB2 |

| Aluminum Castings: | AL101 、ZL114A |

Processing capability

| Surface finish: | Ra1.6-Ra3.2 |

| Dimensional tolerance: | VDG P690 D2 |

| Maximum size: | ≤1200mm×800mm×400mm |

| Weight range: | 0.1kg-120kg |

Design Ability &Mold Flow Analysis

We have an excellent design team who canuse mold flow analysis simulation for designevaluation and mold manufacturing predictionWe pay attention to the needs of customersand give them valuable suggestions to ensurethat the production cost is improved whileimproving product functions.