- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

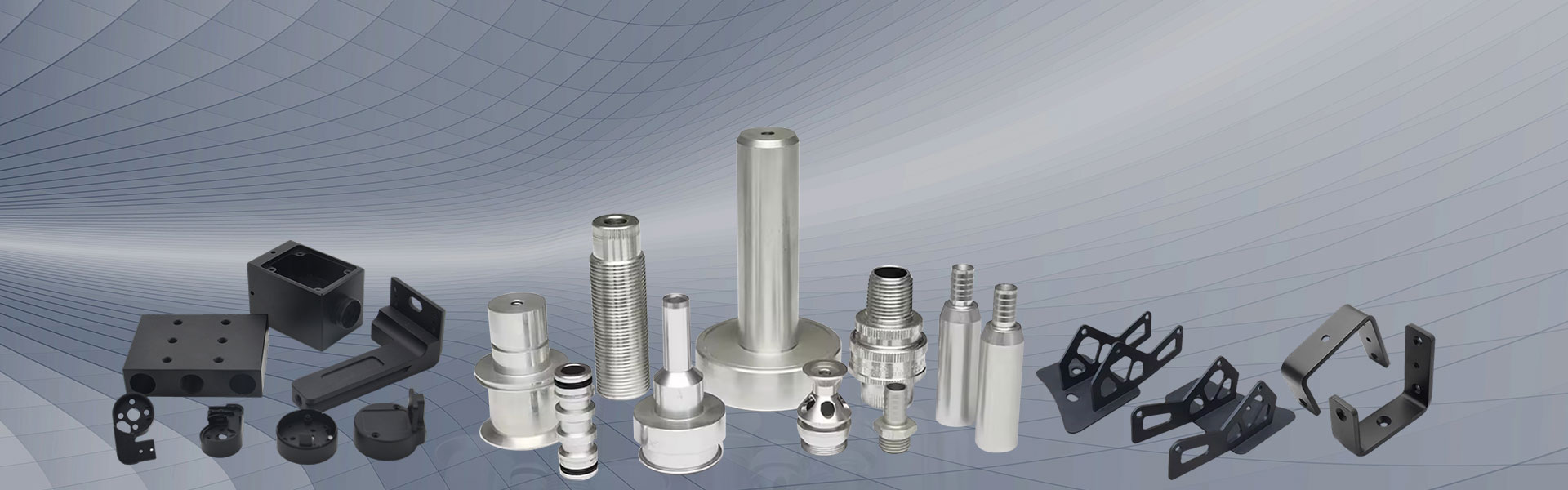

CNC Turning Accessories

Send Inquiry

As the professional manufacturer, we would like to provide you KwongTo CNC Turning Accessories. Here are some common CNC turning accessories:

Chucks: Chucks are used to securely hold the workpiece in place during machining. They come in various types, such as three-jaw chucks, collet chucks, and hydraulic chucks, offering different levels of grip and precision.

Tool Holders: Tool holders securely grip cutting tools and allow for quick and easy tool changes during machining operations. They come in different styles, including turret tool holders, block tool holders, and modular tooling systems.

Collets: Collets are used to hold round workpieces or tooling with a specific diameter. They provide a secure grip on the workpiece or tool, ensuring accurate machining.

Live Tooling Attachments: Live tooling attachments enable CNC turning machines to perform milling, drilling, and other secondary operations without requiring additional setups on separate machines.

Steady Rests and Follow Rests: Steady rests and follow rests support long and slender workpieces during machining, reducing vibration and deflection to ensure accurate results.

Bar Feeders: Bar feeders automate the loading of long bar stock into the CNC turning machine, allowing for uninterrupted production of multiple parts without manual intervention.

Coolant Systems: Coolant systems provide lubrication and cooling during machining operations, helping to extend tool life, improve surface finish, and evacuate chips from the cutting zone.

Chip Conveyors: Chip conveyors remove chips and swarf from the machine's work area, preventing buildup and ensuring continuous operation.

Part Catchers and Ejectors: Part catchers and ejectors automatically remove finished parts from the machine's work area, improving productivity and reducing cycle times.

Tool Presetters: Tool presetters accurately measure and set tool offsets offline, reducing setup times and ensuring precise tool positioning during machining.

Workpiece Probes: Workpiece probes allow for in-process measurement and inspection of workpiece dimensions, ensuring part quality and dimensional accuracy.

Tool Monitoring Systems: Tool monitoring systems detect tool wear, breakage, or other issues during machining, helping to prevent costly damage and downtime.

These accessories enhance the functionality and efficiency of CNC turning machines, allowing manufacturers to produce high-quality turned parts with precision and consistency.

CNC Turning Processing

Machinery Axis: 3,4,5,

Supply Ability:80000Piece/Month

CNC turning is a machining process used to create cylindrical parts by removing material from a rotating workpiece. It is commonly used in manufacturing industries to produce components such as shafts, pins, and fittings.

CNC Sawing Process

Sawing is a metal cutting process used to cut metal materials into the desired dimensions and shapes. It typically involves the

use of saw blades or saw bands to perform the cutting operation by applying rotational or reciprocating motion to cut the material

to the desired size. It is widely used in manufacturing and construction industries. Various metal materials, such as steel,

aluminum, copper, stainless steel, etc.,

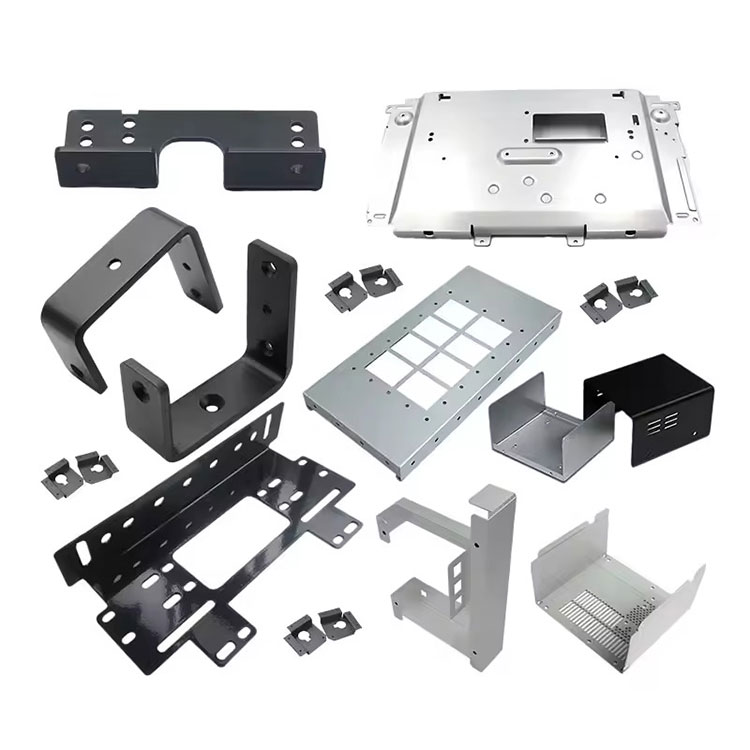

CNC Machining Center

CNC machining is a versatile and precise manufacturing process that utilizes computer-controlled machines to remove material and create complex parts from various materials. It offers advantages such as precision, versatility, efficiency, and reproducibility. By leveraging CNC technology, manufacturers can achieve high-quality results and meet the demands of various industries and applications.