- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

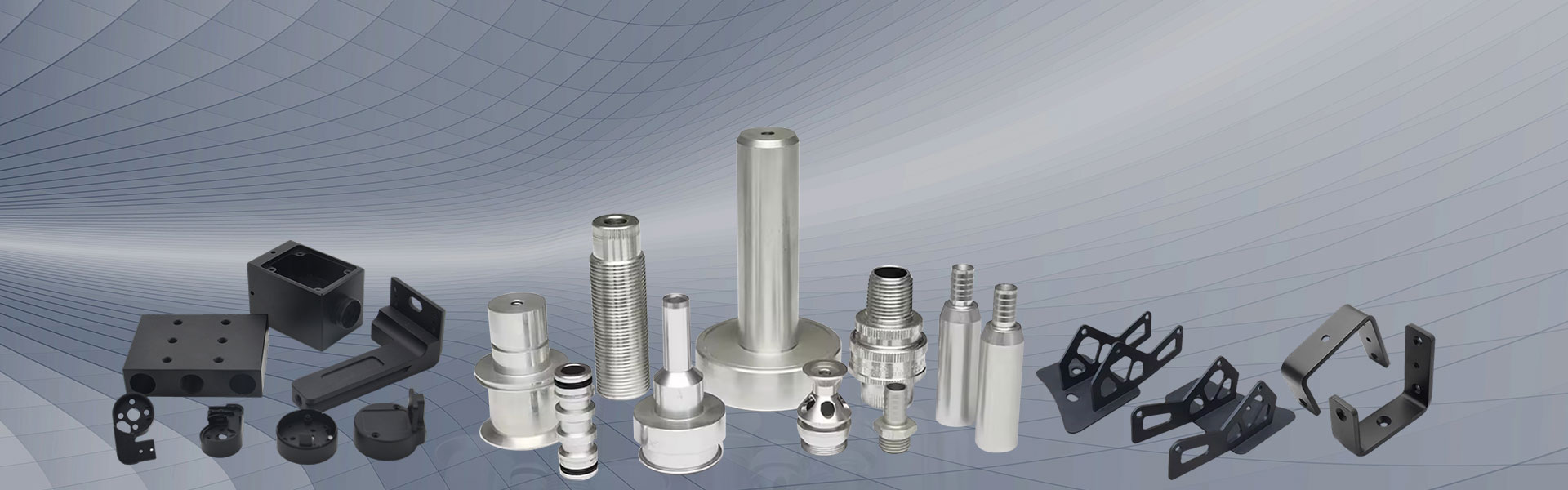

CNC Turning Process

Send Inquiry

You can rest assured to buy CNC Turning Process from our factory. CNC turning is a versatile and efficient machining process used to produce a wide range of cylindrical parts with high precision and consistency. It offers advantages such as reduced setup times, improved repeatability, and the ability to machine complex geometries with ease, making it a preferred choice for manufacturing components in various industries. CNC machining stands out as a highly adaptable and meticulous manufacturing technique employing computer-guided machines to carve out intricate components from diverse materials. Its key strengths encompass precision, adaptability, efficacy, and consistency. With CNC technology at their disposal, manufacturers can attain top-tier outcomes, catering to the diverse needs of industries and applications alike.

CNC Turning Processing

Machinery Axis: 3,4,5,

Supply Ability:80000Piece/Month

CNC turning is a machining process used to create cylindrical parts by removing material from a rotating workpiece. It is commonly used in manufacturing industries to produce components such as shafts, pins, and fittings.

CNC Sawing Process

Sawing is a metal cutting process used to cut metal materials into the desired dimensions and shapes. It typically involves the

use of saw blades or saw bands to perform the cutting operation by applying rotational or reciprocating motion to cut the material

to the desired size. It is widely used in manufacturing and construction industries. Various metal materials, such as steel,

aluminum, copper, stainless steel, etc.,

CNC Machining Center

CNC machining is a versatile and precise manufacturing process that utilizes computer-controlled machines to remove material and create complex parts from various materials. It offers advantages such as precision, versatility, efficiency, and reproducibility. By leveraging CNC technology, manufacturers can achieve high-quality results and meet the demands of various industries and applications.