- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

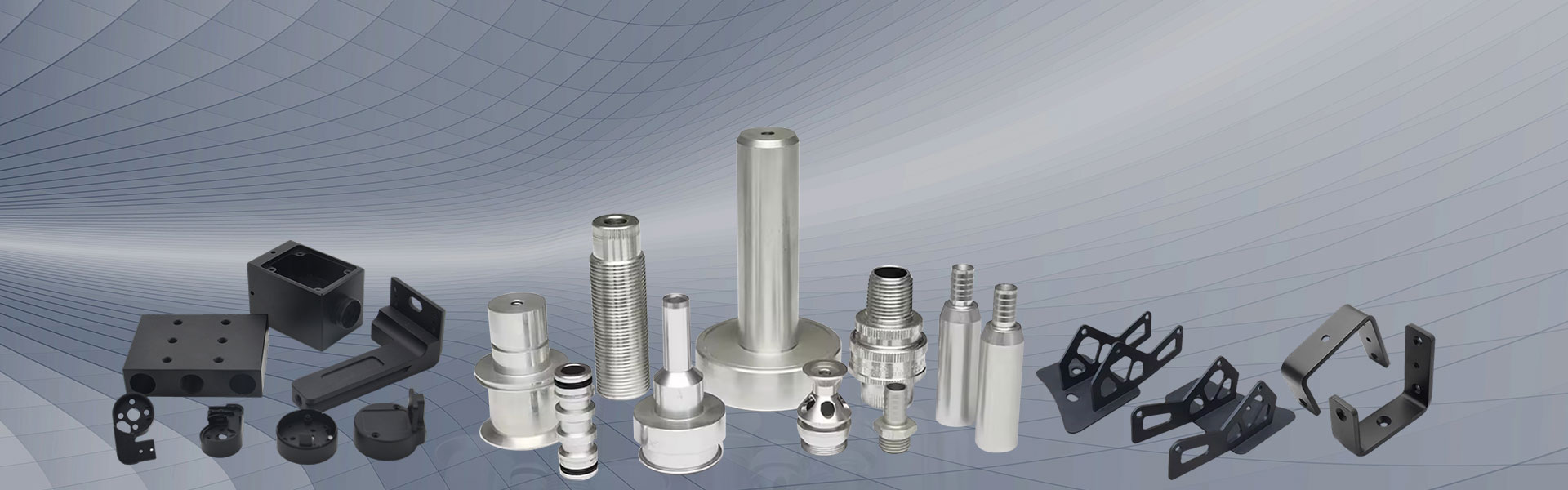

Large Sheet Metal Processing Services

Send Inquiry

As the professional manufacturer, we would like to provide you Large Sheet Metal Processing Services. Design and Engineering: Clients provide specifications or collaborate with the service provider to design large sheet metal components. This includes determining the dimensions, tolerances, material requirements, and any specific features needed for the application.

Material Selection: Depending on the application, a variety of sheet metal materials may be suitable for large-scale fabrication, including steel, aluminum, stainless steel, and others. The choice of material is based on factors such as strength, corrosion resistance, weight, and cost.

Cutting and Forming: Large sheet metal components are cut into the required shapes and sizes using specialized cutting equipment such as plasma cutting, laser cutting, or waterjet cutting. Forming processes such as bending, rolling, and press braking are then used to shape the metal into the desired configurations.

Welding and Joining: Large sheet metal components may require welding or joining to assemble complex structures. Skilled welders use techniques such as MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, or submerged arc welding to create strong and durable connections between metal parts.

Machining and Finishing: Depending on the application and requirements, large sheet metal components may undergo additional machining operations such as drilling, milling, or tapping to create holes, threads, or mounting points. Finishing processes such as deburring, grinding, painting, powder coating, or plating may also be applied to improve surface finish, appearance, and corrosion resistance.

| Material | Carbon steel, SPCC, SGCC, Stainless steel, Aluminum,Brass, Copper, Titanium, Alloy etc |

| Process | Laser Cutting, Precision Stamping, Bending, Welding, CNC milling, CNC Tuming , Threading, Riveting, Dillig, CNC Punching, Die Casting etc |

| Surface treatment | Brushing, Polishing, Vacuum Plating, Anodizing, Powder Coating, Zinc Plating, Chrome Plating, Nickel Plating, Tin plating, etc. |

| MOQ | 1 PC |

| Size | Customized Size |

| Color | RAL, Pantone, RGB, CMYK |

| Drawing format | DWG, DXF, STEP, IGS, 3DSSTL, SKP, AI, PDF |

| Package | carton, wooden box |

| Place of Origin | Guangdong,China |

| Service | OEM/ODM |

Why choose us?

1. OEM/ODM is welcome.

2. All kinds of sheet metal processing services are available.

3. Electroplating, Dacromet, anodizing, powder coating, and painting are available.

4. Multiple secondary processing such as reaming, drilling, heat treatment, electroplating, and painting are available.

5. Good assembly by welding, mounting, sticker pasting, and customized packaging.

6. Small orders are acceptable and well arranged.

7. 2D, 3D drawings are available for modification.

8. Professional service team to provide you with fast and efficient service.

Any question related to our metal parts, our experienced engineers are ready to help.