- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

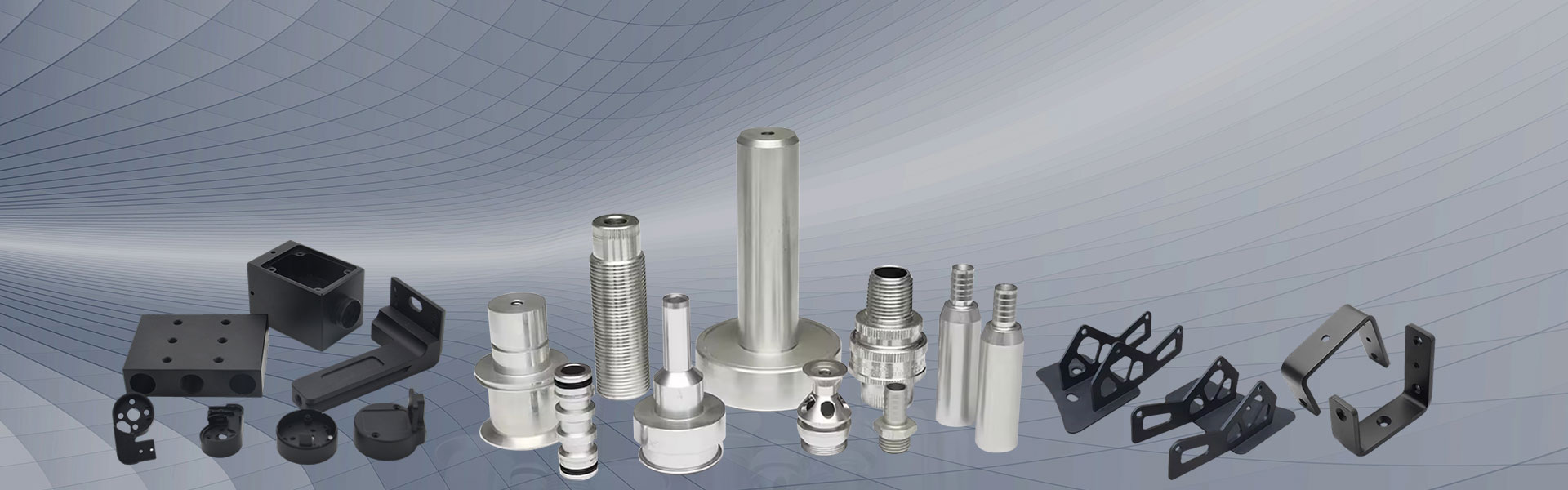

Substation Box Sheet Metal Processing Services

Send Inquiry

As the professional manufacturer, we would like to provide you Substation Box Sheet Metal Processing Services. Sheet metal processing services for substation boxes usually entail several steps:

Design and Engineering: Clients provide specifications or collaborate with the service provider to design the substation box components. This involves determining dimensions, materials, and any special features required for the application.

Material Selection: Sheet metal processing services offer a range of materials suitable for substation boxes, including steel, aluminum, and stainless steel. The choice of material depends on factors such as durability, corrosion resistance, and cost.

Cutting and Forming: Sheet metal is cut into the required shapes and sizes using techniques such as laser cutting, plasma cutting, or waterjet cutting. It is then formed into the desired shapes using processes like bending, stamping, or punching.

Welding and Assembly: Components may need to be welded together to create the final substation box structure. Skilled welders use techniques such as MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding to join metal parts securely. Assembly involves putting together all the fabricated parts to create the finished product.

Finishing: Substation box components may undergo finishing processes such as painting, powder coating, or galvanizing to enhance their appearance and provide additional protection against corrosion and environmental factors.

Quality Assurance: Throughout the manufacturing process, quality control measures are implemented to ensure that the substation box components meet the required specifications and standards. This may involve dimensional inspections, material testing, and visual inspections.

Packaging and Shipping: Once the substation box components are complete and inspected, they are carefully packaged to prevent damage during transportation and shipped to the client's location or installation site.

Sheet metal processing services for substation boxes require precision, expertise, and adherence to safety and quality standards to ensure the reliability and performance of the final product in electrical infrastructure applications.

| Material | Carbon steel, SPCC, SGCC, Stainless steel, Aluminum,Brass, Copper, Titanium, Alloy etc |

| Process | Laser Cutting, Precision Stamping, Bending, Welding, CNC milling, CNC Tuming , Threading, Riveting, Dillig, CNC Punching, Die Casting etc |

| Surface treatment | Brushing, Polishing, Vacuum Plating, Anodizing, Powder Coating, Zinc Plating, Chrome Plating, Nickel Plating, Tin plating, etc. |

| MOQ | 1 PC |

| Size | Customized Size |

| Color | RAL, Pantone, RGB, CMYK |

| Drawing format | DWG, DXF, STEP, IGS, 3DSSTL, SKP, AI, PDF |

| Package | carton, wooden box |

| Place of Origin | Guangdong,China |

| Service | OEM/ODM |

Why choose us?

1. OEM/ODM is welcome.

2. All kinds of sheet metal processing services are available.

3. Electroplating, Dacromet, anodizing, powder coating, and painting are available.

4. Multiple secondary processing such as reaming, drilling, heat treatment, electroplating, and painting are available.

5. Good assembly by welding, mounting, sticker pasting, and customized packaging.

6. Small orders are acceptable and well arranged.

7. 2D, 3D drawings are available for modification.

8. Professional service team to provide you with fast and efficient service.

Any question related to our metal parts, our experienced engineers are ready to help.